Closing Machines

Flip Top Cap Closing Machine

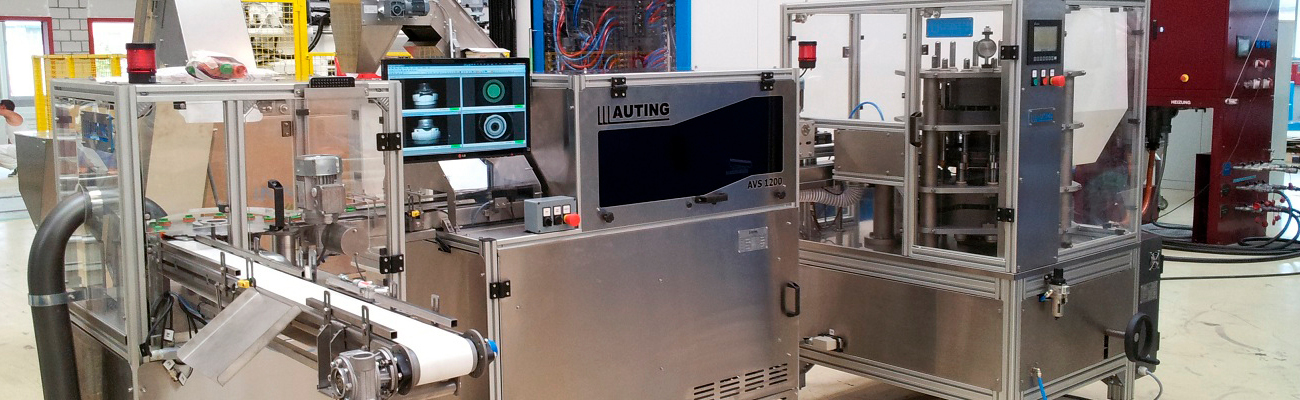

AUTING has developed reliable cap closing technologies and equipment in order to provide our clients quality and efficiency to their production line. Without breaking hinges or even force and deform any cap.

We offer two types of equipment, we will find out which one is more suitable for your request:

These Cap Closing Machines can work in line with the Injection machine or with a pre-heating equipment to warranty a better process in the closing operation.

All our equipment are provided with vibratory hopper or hopper elevator depending on our engineering.

Combining or Incorporating a flip-top to a plastic, or any related material, enclosure is an important aspect of the pharmaceutical industry as well as the processing and packaging industry. Injection molding companies have a clear and strong demand for high-quality, low-cost solutions.

Integrating the automatic flip top cap closing system into the automatic assembly machine is a brilliant idea to grow your business while reducing costs. You can contact our design team to build an automatic capping system for various flip caps.

The system uses top covers (opened after injection molding) and closes them before the packaging company or manufacturer uses them.

CAP WADDING SYSTEM - EQUIPMENT YOU CAN TRUST

Our high-tech flip top cap closing machines meet your requirements with a wide range of closure styles with various hinge and latch features. We manufacture several styles of machines: Continuous Rotary Motion; Continuous Linear Motion; Rotary Indexing and Linear Indexing. Let our team share and show you their experience in order to help you select the ideal system.

What are the most important features of capping equipment?

At Auting we think that flexibility, simple changeovers and reliability (easy to maintain) are some of the most important features of capping equipment.

A closer that can be adjusted to handle a range of container shapes and cap sizes and that can be upgraded to grow with a customer's needs will often prove to be a better long-term investment.

A closer must also be easy to adjust, otherwise, the ability to handle multiple closures and containers would not be a great feature. Auting's closers are designed to use a minimum of change parts, allowing for quick and easy changeovers in 30 minutes.

Finally, a capper must be reliable. Auting closers are designed with as few moving parts as possible and all parts are standardized. Fewer parts means less chance of parts failure and easier routine maintenance.